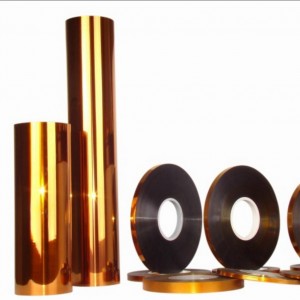

Polyimide Film for H-class motors, Electrical Insulation and Other Electrical Purposes.

Product Description

The polyimide film is produced by the ” film casting”, which has high temperature resistance, radiation resistance and excellent dielectric properties. It is widely used in H-class motors, electrical insulation and other electrical purposes.

Standard No.: JB/T 2726-1996

Skills requirement

- Appearance: The surface of the film is smooth and smooth, and there should be no defects such as wrinkles, tears, particle bubbles, pinholes and foreign impurities. The edges are neat and without damage, and the film is supplied in rolls.

- Size

- Thickness and allowable deviation: recommended thickness, Custom thickness aalso available upon request.

- Width and length: supplied according to customer requirements.

Datasheet

|

NO |

Index descnption |

Unit |

Index Value(TY6051) |

||||||||||||||

|

1 |

Standardthickness |

µm |

25 |

40 |

50 |

75 |

100 |

125 |

175 |

200 |

|||||||

|

2 |

Allowable tolerance |

µm |

+4 |

+6 |

+7 |

+8 |

+10 |

+8 |

+8 |

+8 |

|||||||

|

3 |

Density |

Kg/m³ |

1420±20 |

||||||||||||||

|

4 |

Tensile |

Longitudinal |

Mpa |

≥135 |

|||||||||||||

|

5 |

Elongation |

Longitudinal |

% |

≥35 |

≥50 |

≥50 |

|||||||||||

|

6 |

Hot- |

150℃ |

% |

≤1.0 |

|||||||||||||

|

7 |

Frequency |

Average value |

MV/m |

≥150 |

≥130 |

≥110 |

≥100 |

≥100 |

|||||||||

|

8 |

Volume resistivity at 200℃ |

Ωm |

≥1.0×1010 |

||||||||||||||

|

9 |

Surface rssistivity at 200℃ |

Ω |

≥1.0×1013 |

||||||||||||||

|

10 |

Relative dielectnic constant |

- |

3.5±0.4 |

||||||||||||||

|

11 |

Dielectric dissip ation factor |

- |

≤4.0×10-3 |

||||||||||||||

|

12 |

Long tenm heat resist ance |

℃ |

≥380 |

||||||||||||||

Packaging mark, storage and transportation

- The film is supplied in rolls on the core, each roll is sealed in a plastic tape and placed in a dry, clean carton.

- Each package should indicate the model number, product name, specifications, batch number, gross weight, factory name, and date of manufacture. It is accompanied by a product inspection certificate. At the same time, the words “moisture proof” and “anti-shock” are indicated on the package.

- The film should be stored in a dry and clean room. The storage period is two years from the date of shipment. Once exceeds the storage period, it can still be used if it passes the standard inspection.

- Avoid moisture and mechanical damage during storage and transportation.